American Ergonomics Corporation

Innovative Seat Technology for Comfort and Safety

CBM Dynamic Seat for Aircraft Main Cabin

The Counter Balanced Motion (CBM) Seat is American Ergonomics Corporation's (AEC) dynamic seat concept. The CBM Seat is extensively developed to complement the dynamics of the seated human body for the transportation industry. It has a self-adjusting seat motion mechanism designed to respond automatically to movements, improving passenger comfort and safety. This mechanism is the most practical design for the next generation of seating. It allows automatic seat adjustment without motors, hydraulics, or control units. And it offers optimal seating comfort, space, and safety solution for aircraft main cabin and business customer seating.

Seat backrest upwards reclined

The CBM Seat design positions the center of motion at the center of the occupant's body mass to provide the path of least resistance. For example, if an axel is placed in the perfect center of mass of a wheel, it will roll smoothly, last practically forever and will give the most comfortable ride. If the axel is placed out of center, it will give a bumpy ride and will not be as comfortable. It will need other mechanisms and counter weights to compensate for the instability, making it heavier, unreliable and costly. The CBM Seat definitely produces an 'Ahh' response when it automatically self-adjusts for the passenger.

Seat inclined downwards and upwards

The primary reason the CBM Seat works well for safety is that the center or axis of motion of the seat rotation is proximate to the center of mass of the seated body. This allows the seat to restrain the lower body and reduce head trajectory. The center of motion is substantially fixed relative to the floor and the base supporting structure of the seat. 'Substantially fixed' means that the axis of rotation does not move during the deployment of the seat pan from horizontal to steeply upwards. As long as the axis of seat rotation remains substantially fixed proximate the center of mass of the body during deployment, the seat will obtain the necessary containment angle to restrain the lower body along the seat's counter wise trajectory thus causing the reduction of head trajectory.

CBM seat and backrest normal use positions between comfort self-adjusted postures.

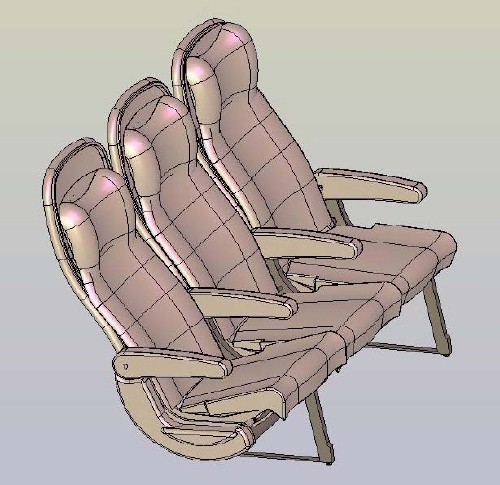

Now, AEC presents designs that are an evolution of the first two triplets concept seats retrofitted with CBM mechanisms built for Boeing by AEC.

New CBM Seat Designs Features and Properties

AEC has several new and optimized CBM dynamic seat designs for aircraft passenger seating utilizing arcuate motion, thus complementing seat mechanics to body dynamics. The aim of the CBM seat is to improve comfort, safety, weight, space, cost and style. The CBM Seat models presented are designed with selected features for short and/or long-range flights as follows:- Self-Adjusting CBM seat mechanism with dynamic equilibrium provides optimized passenger

- comfort with passive, automatic adjustment of the seat, backrest and headrest. The seat motion

- works from the center of mass of the body (about belly button) to allow the body to articulate in

- balance to easily rotate around its own center between upright and reclined postures.

- Without requiring motors, pumps, or controls the well-balanced CBM Seat mechanism easily moves to accommodate the range of seated positions.

- Seat, backrest and headrest have dynamic paths of motion that automatically maintain continuous support between upright and reclined postures. Models with Seat and Lumbar motion combinations work with standard back support frame. Two additional types of backrest configurations have either one-piece rigid body articulated backrest frame or a two-piece backrest that has a second articulation of the upper to lower backrest cushion.

CBM Seat Weight Reduction Advantages

The CBM Seat dynamics makes it possible to decrease weight without sacrificing comfort or safety.- Significant volume of material can be deleted in models 600and 700, such as parts for the back recliner mechanism as the Hydraulic cylinder, brackets, bushings, controls, tray table legs and cables. Weight can be reduced in models 500 and 800 due to lower force requirements.

- The CBM Lap Belt Anchor Point being lower than SRP is a weight savings factor because a lower lever arm and torque will be acting against the floor. Therefore, the Leg Assembly can by made with less mass to withstand the 16 g test accelerations,

- Light Weight materials can be used. There are several material characteristics that can be used that are lighter and stronger, such as new aluminum alloys, carbon fibers and composites.

- Air chamber cushions can significantly reduce weight for the seat, backrest and headrest. The unique design of the Seat-Pan, as an example, similar to a salad bowl, lends itself to the use of an air cushion inside, thus reducing the amount of weight of polyurethane foams.

CBM Models

Model #500 has an optimized, upwardly arcuate seat motion from the center of the body together with the reclining backrest and translating headrest motions. This is similar dynamics to the prototype built for Boeing but with a redesigned mechanism and structural frame and optimized centers of motion. This design has the typical recliner mechanism that adds recline to the CBM motion. The function with typical recliner is shown in three positions (back 105-130 _ ), upright, mid-recline and fully reclined.

Model #600 has an optimized, upwardly arcuate seat path motion from the center of the body together with the reclining backrest and headrest motion. This design adds recline with the CBM motion to a fixed recliner frame structure without the addition of the typical recliner mechanism. The CBM Seat is shown in three positions, upright, mid-recline and fully reclined.

- Two types of recliner support frame designs In one the CBM Seat provides backrest reclining capability (115 to 125 _ ) with a fixed recliner support frame that is independent of the traditional hydraulically activated recliner assembly. In another type, the recliner frame is additionally reclined to 130 _ with the use of the typical adjuster assembly. In short and medium range flights, the reclining mechanism could be deleted without sacrificing the comfort of back reclining to a significant extent. And the CBM backrest reclines without intruding on the space of the passenger seated behind.

Model #700 has a fixed recliner frame structure without the typical recliner assembly and an optimized, upwardly arcuate seat motion from the center of the body, coupled together with the reclining backrest as one piece with the headrest motion. In addition to the upward curve motion from the center of the body, this model has a component that allows the front of the seat to move downwardly toward the floor after the end of the upward movement. The headrest tilts back and downwards rather than translate as the 500 and 800 models. Back recline is provided only with the CBM motion and without intruding on the space of the passenger seated behind.

Model #800 has an optimized, upwardly arcuate seat motion from the center of the body together with the reclining backrest and translating headrest motion. This adds the CBM dynamic recline to the usual adjustable back recliner frame structure. In addition to the upward curve motion from the center of the body, this model has a component that allows the front of the seat to move downwardly toward the floor after the end of the upward movement. This provides for more extended leg and further backrest recline for a comfortable sleeping posture (backrest to 130 _ ). The CBM Seat is shown in three positions, upright, mid-recline and fully reclined.

- Two types of seat paths of motion One is generally in the vertical plane and fore and aft direction moving around one or more generally transverse axis of rotation. This path is predominantly upwardly arcuate. Another includes a compounded seat path of motion that is upwardly arcuate followed by a short, downwardly arcuate path. This lowers the seat cushion to allow stretching of the legs and increases the back recline.

- The CBM Seat is a stable, reliable and safe restraint system, complementing the belt. It increases stability to better hold the person in the seat. It restrains during any fore and aft and some lateral and or vertical acceleration. This protects the passengers because it restrains the lower body and reduces head trajectory.

- Reduction of musculoskeletal stress and fatigue caused by sitting for extended periods. The CBM Seat promotes motion and changes in seating posture thus improving potentially slow blood flow and may reduce blood clotting caused by long periods of constant sitting.

- Seat suspension The CBM seat mechanism absorbs shocks from turbulence or hard landing. Testing under the ISO 2631-1 frequencies for health, comfort, perception, and motion sickness show notable improvement over standards seats.

- The CBM Seat is user friendly because it self-adjusts without the need of hand activated controls

- Enhanced privacy When a person reclines in the CBM Seat with the seat inclining up and forward, the head, together with the headrest, moves down while the upper back cover acts as a partition, covering the head of the seated passenger.

- Other advanced features such as spherical seat path of motion to allow lateral as well as motion in the fore and aft direction about the body's CG, and center of spherical rotation, may allow side resting and some sideways sleep with improved support.

Patents Granted and Pending

The optimal path of motion for comfortable and safe seating is patented in the United States, Europe, Japan and Hong Kong and currently has several CIP and PCT additional filings on current developments of CBM technology. The patents and pendings dealing with the CBM Seat technology are published in the name of Hector Serber as follows:Seat Assembly and Method US. 5,244,252 Granted Sept. 14, 1993

Seat Assembly and Method US. 5,460,427 Granted Oct. 24, 1995

Seat and Lumbar Motion Chair, Assembly and Method. US. 5,558,399 Granted Sept. 24, 1996 Seat and Lumbar Motion Chair, Assembly and Method. US. 5,735,574 Granted April 7, 1998

Seat Assembly and Method. Japan Patent JP. 3-518615 Granted April 13. 2001

Seat Assembly and Method. Hong Kong # 1012313 Granted May 5, 2000

Dynamically Balanced Seat Assembly. UK # 2406047 Granted Nov. 11/ 2005

Seat Assembly with Moveable Seat and Backrest and Method.

Patent Cooperation Treaty, (PCT) WO 2005/108158 A2 Publication Nov. 17, 2005

Dynamically Balanced Seat Assembly Having Independently and Arcuately Movable Seat

and Backrest and Method. Australia 200326181 Publication Nov. 7, 2005

Dynamically Balanced Seat Assembly Having Independently and Arcuately

Movable Seat and Backrest and Method. US. 10/175,452 Filed July 18, 2002

Seat Assembly with Movable Seat and Backrest and Method. US. 10/836964 Filed April 30, 2004

Seat Assembly with Movable Seat and Backrest and Method. US. 11/276,068 CIP Filed November 3, 2005